Demystifying the 2 Speed Motor Control Wiring Diagram

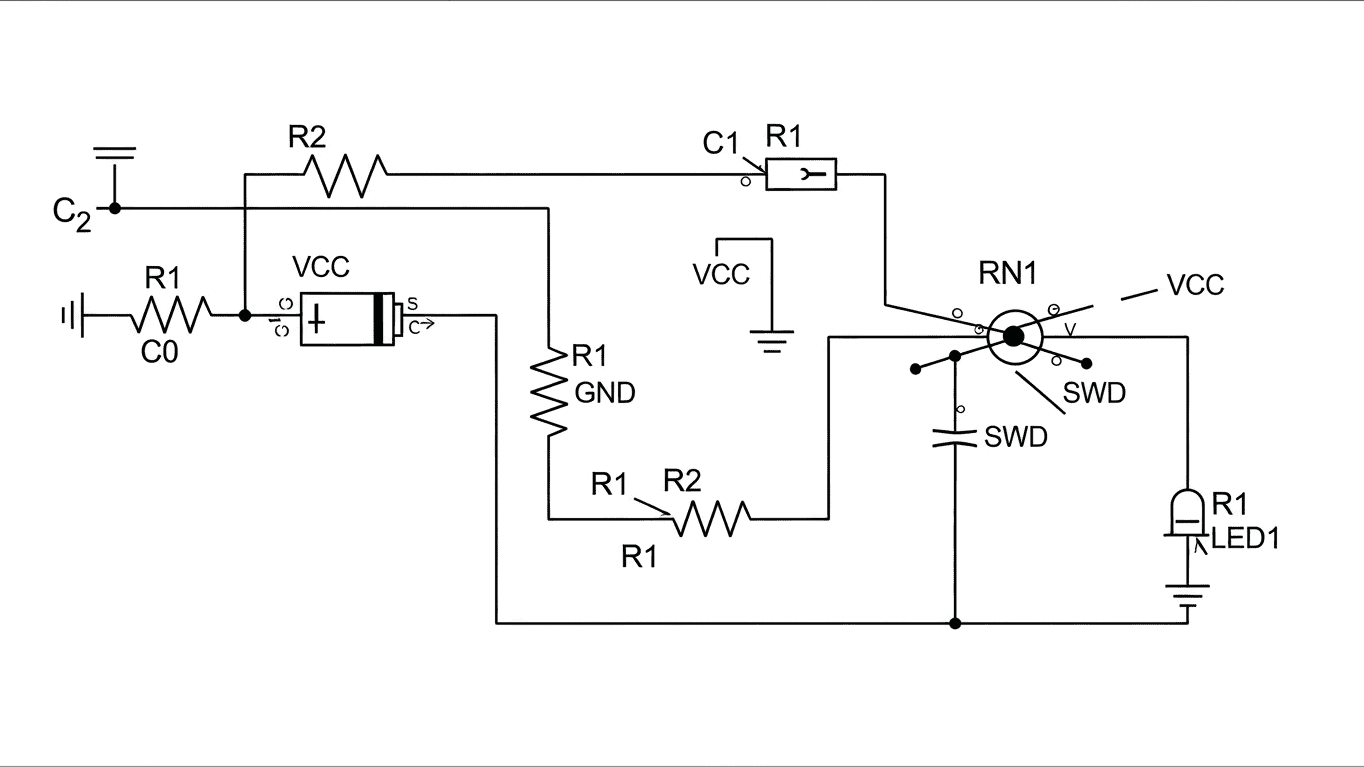

At its core, a 2 Speed Motor Control Wiring Diagram is a schematic that illustrates how to connect a motor to a power source in a way that allows it to run at two different speeds. This is typically achieved by altering the electrical configuration of the motor's windings. Think of it like having two gears for your motor: a lower gear for slower, more controlled movement and a higher gear for faster, more powerful operation. These diagrams are crucial for applications where a single motor needs to adapt to varying demands. For instance:- Ventilation Systems: A fan might need a low speed for quiet, continuous air circulation and a high speed for rapid cooling or exhaust.

- Pumps: A pump could operate at a slower speed to conserve energy during low-demand periods and at a higher speed to meet peak requirements.

- Machinery: Many machines require different speeds for different operational phases, such as a slow speed for precise setup and a fast speed for production.

- Dual Windings: Some motors are designed with separate sets of windings, each producing a different speed when energized. The wiring diagram shows how to select which winding is active.

- Tapped Windings: Other motors have a single winding with multiple connection points (taps). By changing the connection points, the effective length of the winding is altered, resulting in a different speed.

To delve deeper into the practical application and understand the specific connections for your setup, consult the detailed wiring diagrams provided in the next section.