Understanding the intricacies of a 2 Speed Starter Wiring Diagram is crucial for anyone working with machinery that utilizes this type of starting system. Whether you're a hobbyist restoring an old piece of equipment or a professional technician diagnosing a problem, a clear grasp of this diagram ensures proper functionality and prevents costly errors. This article will guide you through the essentials of a 2 Speed Starter Wiring Diagram, making it accessible and understandable.

What is a 2 Speed Starter Wiring Diagram and How It Works

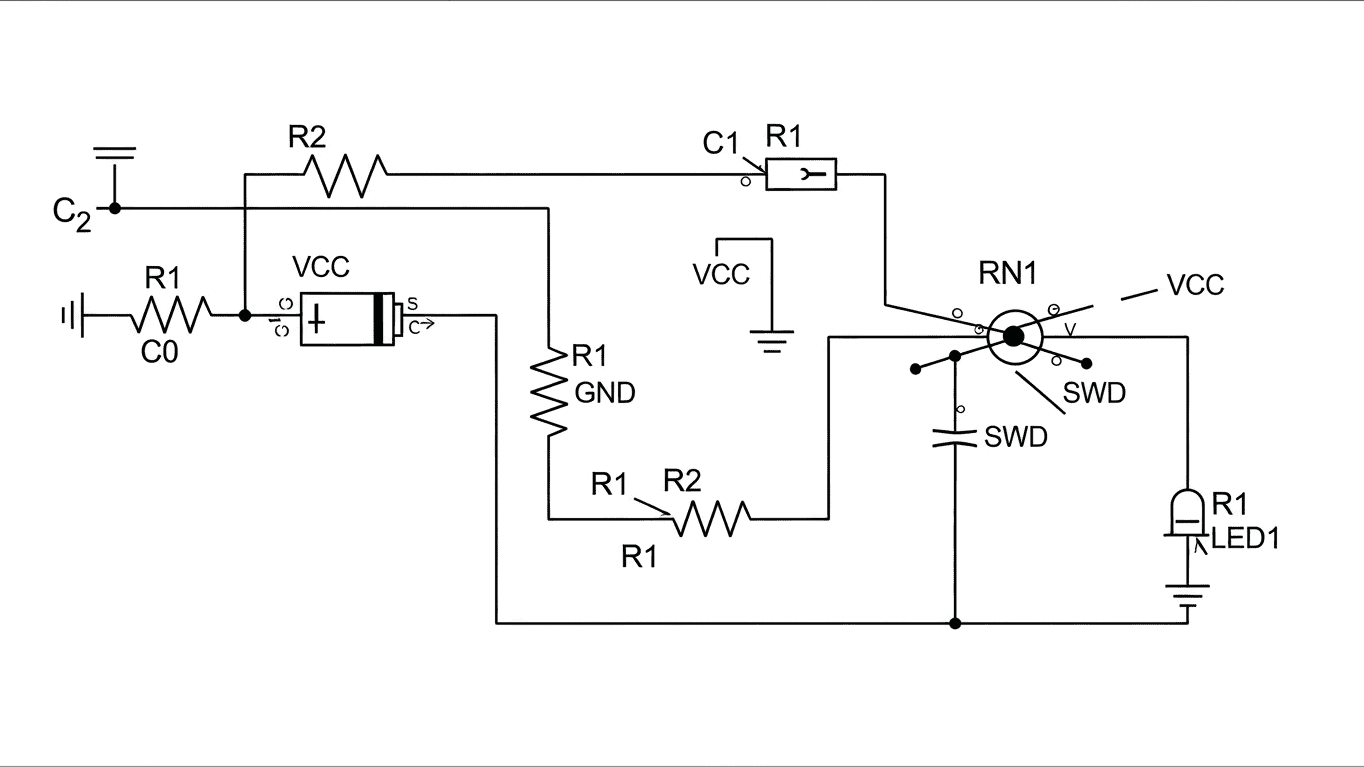

A 2 Speed Starter Wiring Diagram is a schematic illustration that outlines how the electrical components of a two-speed starter motor are interconnected. Unlike single-speed starters, which have a single engagement point for the engine's flywheel, two-speed starters are designed with two distinct operational stages. This allows for a more controlled and efficient start, particularly for larger or more complex engines. The primary benefit of a two-speed starter is its ability to provide a slower, higher-torque initial crank to overcome the engine's initial resistance, followed by a faster crank for a more sustained start. This staged approach reduces stress on the starter motor and the engine itself.

The components typically found in a 2 Speed Starter Wiring Diagram include:

- The starter motor itself, which contains both low-speed and high-speed windings.

- A starter solenoid, which acts as an electrically operated switch.

- Various relays, often including a timer relay or a control relay.

- The ignition switch or starting button.

- Battery power source.

The operation usually begins when the ignition switch is turned to the "start" position. This energizes a control circuit that activates the solenoid. The solenoid then engages the starter motor's drive mechanism with the engine's flywheel. Simultaneously, the electrical current is directed through the low-speed windings of the starter motor. Once the engine reaches a certain RPM or a timer relay operates, the wiring is reconfigured to bypass the low-speed windings and direct current to the higher-speed windings, providing the necessary momentum for the engine to fire and run independently. The precise sequence of these electrical transfers is what makes the 2 Speed Starter Wiring Diagram so important.

Here's a simplified overview of the typical stages:

- Initial Crank (Low Speed): Battery power is sent to the solenoid, which engages the starter gear. The current flows through the low-speed windings of the starter motor, providing high torque at a lower RPM.

- Transition: A control signal (often from a timer or engine RPM sensor) triggers a change in the circuit.

- Sustained Crank (High Speed): The wiring is rerouted to engage the high-speed windings. This allows the starter motor to spin faster, helping the engine achieve running speed.

- Disengagement: Once the engine starts, the ignition switch is released, de-energizing the solenoid and disengaging the starter.

Understanding the flow of electricity through these stages, as depicted in the diagram, is key to troubleshooting and repairs.

For a more in-depth understanding and to see how these components are precisely linked, refer to the specific 2 Speed Starter Wiring Diagram relevant to your equipment.