Navigating the electrical connections of a two-speed pump can seem daunting, but a clear understanding of the 2 Speed Pump Wiring Diagram is key to ensuring safe and efficient operation. Whether you're a homeowner looking to maintain your pool or spa, or a technician performing repairs, deciphering this diagram is a crucial first step. This guide will break down the essential aspects of a 2 Speed Pump Wiring Diagram, making it accessible for everyone.

What is a 2 Speed Pump Wiring Diagram and How is it Used?

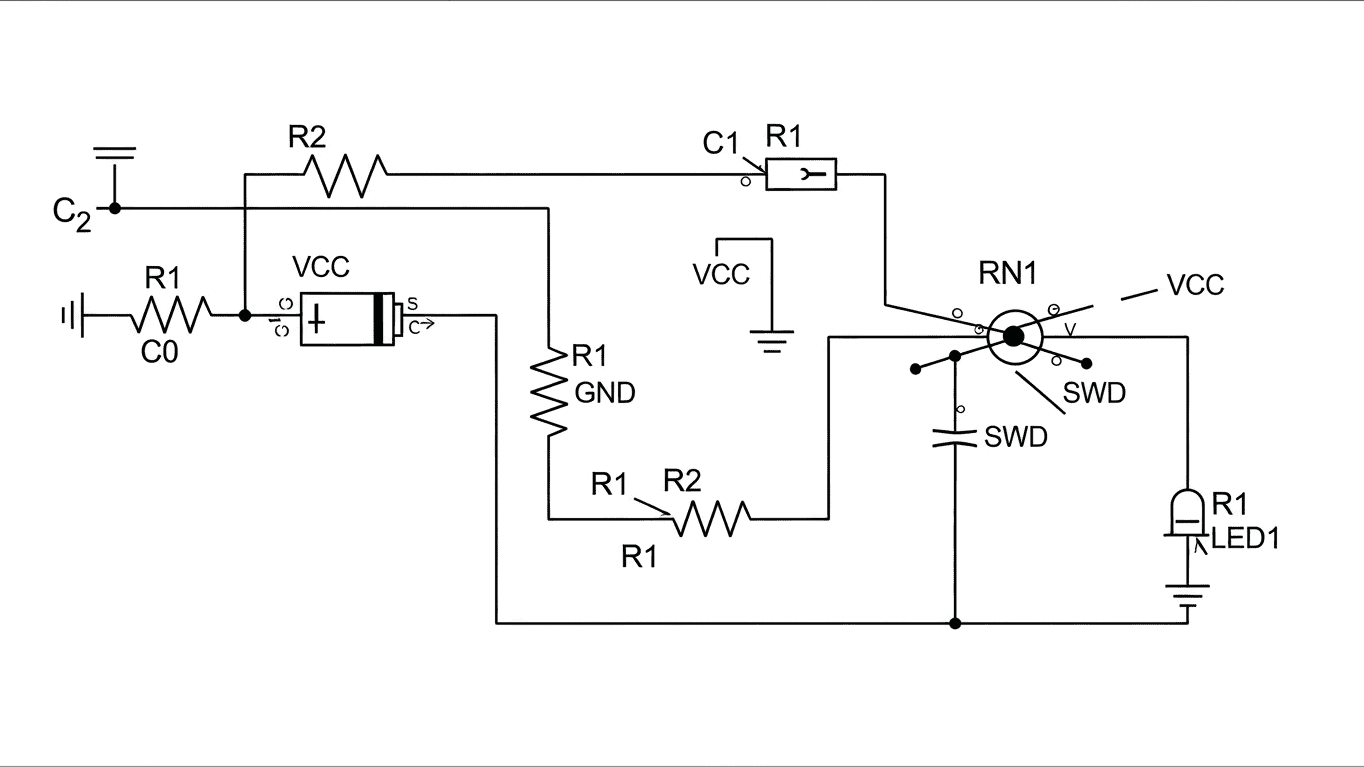

A 2 Speed Pump Wiring Diagram is essentially a blueprint that illustrates how the electrical components of a two-speed pump are connected. It shows the path electricity takes from the power source to the motor, detailing how the different speeds are achieved. These diagrams are vital for installation, troubleshooting, and repairs. By following the lines and symbols, one can identify the power supply, the motor windings, capacitors, switches, and any control devices like timers or relays.

Two-speed pumps are designed to offer flexibility and energy efficiency. They typically have a low-speed setting for normal filtration and a high-speed setting for tasks requiring more power, such as running a spa or a cleaning system. The 2 Speed Pump Wiring Diagram explains the intricate switching mechanism that allows the motor to draw power differently to achieve these distinct speeds. Without a proper diagram, connecting these wires incorrectly can lead to motor damage, electrical hazards, or the pump simply not functioning as intended. The importance of using the correct 2 Speed Pump Wiring Diagram cannot be overstated for safety and optimal performance.

The components you'll commonly find represented in a 2 Speed Pump Wiring Diagram include:

- Power Source: Indicates the incoming voltage (e.g., 110V, 220V) and ground connections.

- Motor Windings: Different sets of wires within the motor that are energized to create distinct speeds.

- Capacitors: Often used to help the motor start and run efficiently at its designated speeds.

- Switches/Relays: These components are responsible for directing power to the correct windings to select high or low speed.

- Control Devices: Such as timers or external control panels that send signals to the pump's internal switching mechanisms.

| Connection Point | Low Speed | High Speed |

|---|---|---|

| Line 1 | Winding A | Winding B |

| Line 2 | Winding C | Winding C |

| Common | Winding D | Winding D |

For a precise understanding tailored to your specific pump model, it is highly recommended to refer to the official 2 Speed Pump Wiring Diagram provided by the manufacturer. This ensures you have the most accurate and up-to-date information for your system.