Understanding the intricacies of a 2 Speed Motor Starter Wiring Diagram is fundamental for anyone looking to effectively control and optimize the operation of machinery that requires different speed capabilities. This diagram serves as the blueprint, guiding electricians and technicians through the correct connection of components to achieve dual-speed functionality from a single motor.

Decoding the 2 Speed Motor Starter Wiring Diagram

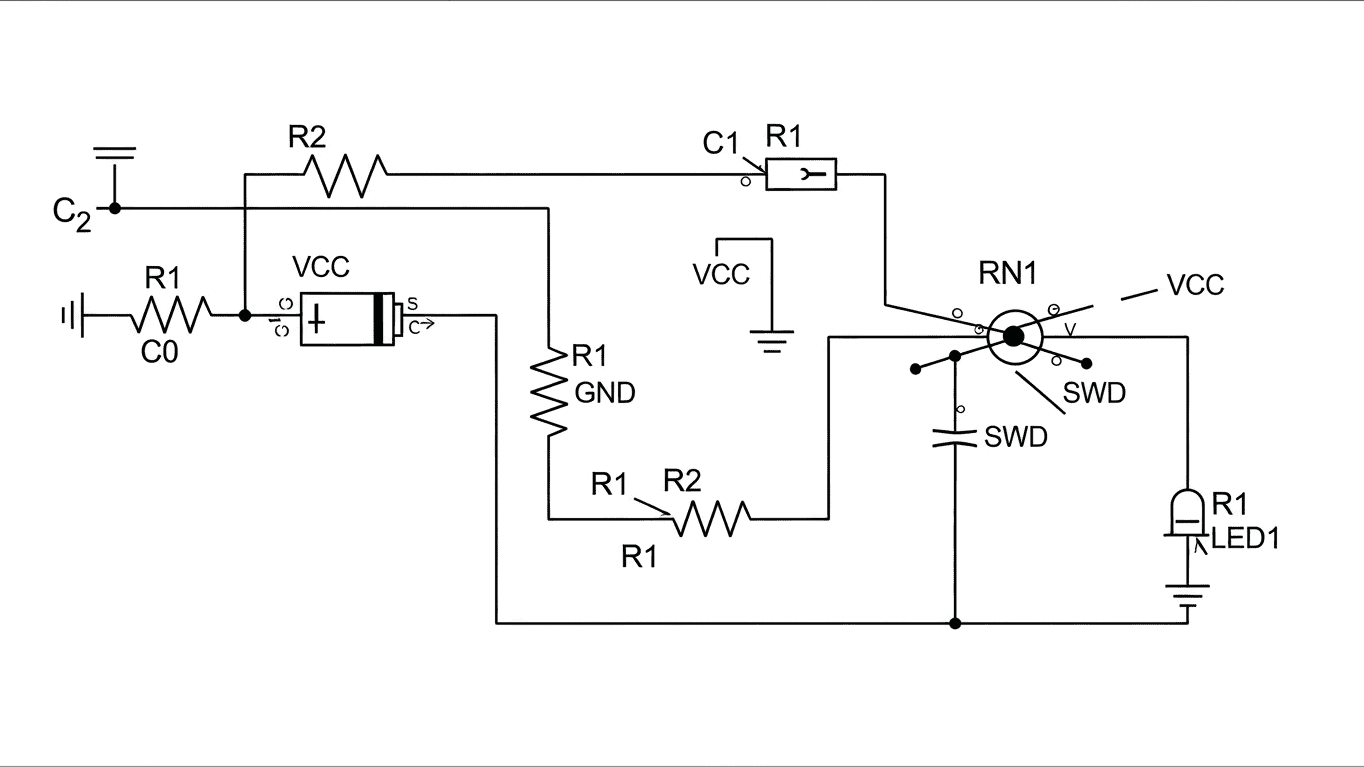

A 2 Speed Motor Starter Wiring Diagram is essentially a visual guide that illustrates how to connect a motor designed to operate at two distinct speeds to its power source and control mechanisms. These motors, often called "two-winding" or "dual-speed" motors, achieve their speed variation through different internal winding configurations. The starter, in conjunction with the wiring diagram, allows for the selection and engagement of these specific windings, thus altering the motor's rotational speed. The correct implementation of a 2 Speed Motor Starter Wiring Diagram is crucial for ensuring safe operation, preventing motor damage, and achieving the desired performance for various applications.

The primary function of a 2 Speed Motor Starter Wiring Diagram is to facilitate the switching between these internal motor windings. Typically, this involves a control device, such as a selector switch or pushbuttons, which directs power to the appropriate set of windings. A common setup might involve a starter with multiple contactors or relays.

- Contactor A: Engages the windings for the lower speed.

- Contactor B: Engages the windings for the higher speed.

- Overload Relays: Protect the motor from excessive current draw, which can occur if both sets of windings are accidentally energized simultaneously or if one winding draws too much current.

Here's a simplified look at how the connections might be structured:

| Component | Function | Speed Selection |

|---|---|---|

| Power Source | Provides electricity | All Speeds |

| Selector Switch | User interface for speed choice | Low/High |

| Contactor A | Connects power to low-speed windings | Low |

| Contactor B | Connects power to high-speed windings | High |

The wiring diagram will meticulously detail the connections between the power supply lines (L1, L2, L3), the selector switch, the motor terminals, and the coils of the contactors and overload relays. It will also show safety interlocks, ensuring that only one speed-selecting contactor can be energized at any given time, preventing a short circuit. For instance, a typical sequence might look like this:

- When the "Low Speed" is selected, the selector switch energizes the coil of Contactor A.

- Contactor A closes its contacts, supplying power to the motor's low-speed windings.

- When the "High Speed" is selected, the selector switch energizes the coil of Contactor B.

- Contactor B closes its contacts, supplying power to the motor's high-speed windings.

Often, a specific wiring arrangement is employed to prevent both contactors from being energized simultaneously. This is frequently achieved through mechanical or electrical interlocks. For example, the contacts of Contactor A might be wired in series with the coil of Contactor B, and vice-versa. This ensures that if Contactor A is active, it breaks the circuit to Contactor B's coil, and vice versa. This interlocking mechanism is a critical safety feature.

To gain a comprehensive understanding and ensure proper installation, meticulously follow the specific 2 Speed Motor Starter Wiring Diagram provided by the motor manufacturer or the control system designer. This detailed guide is the definitive resource for accurately wiring your dual-speed motor system.