Understanding a 2 Speed Axle Wiring Diagram is crucial for anyone working with vehicles or machinery that utilize this specialized transmission system. This diagram serves as a roadmap, illustrating how electrical signals control the engagement and disengagement of different gear ratios within the axle, ultimately allowing for a wider range of operating speeds and torque. Mastering the 2 Speed Axle Wiring Diagram can help diagnose issues, perform maintenance, and even optimize performance.

The Ins and Outs of a 2 Speed Axle Wiring Diagram

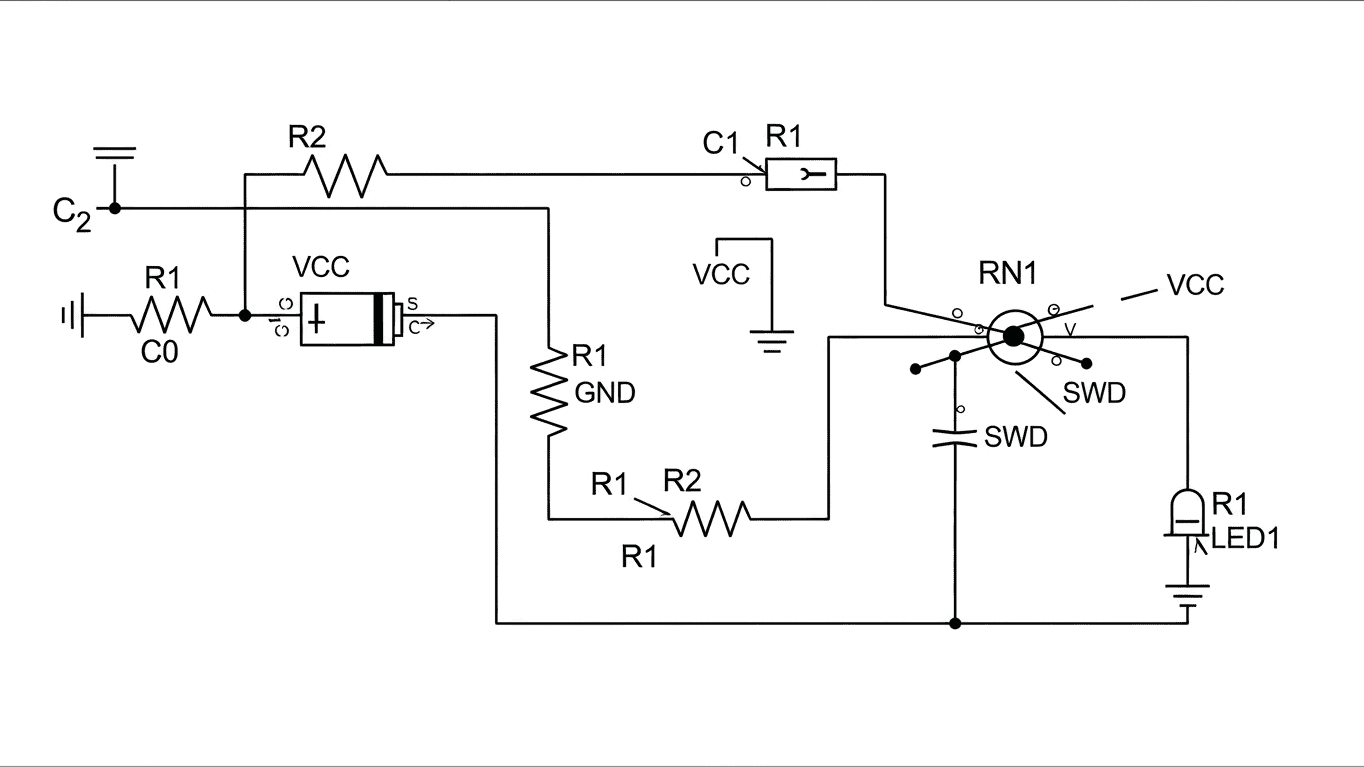

A 2 Speed Axle Wiring Diagram is essentially a schematic that visually represents the electrical connections within a 2-speed axle system. These axles are designed to offer two distinct gear ratios, typically a low gear for increased torque (ideal for heavy loads or climbing) and a high gear for increased speed (suited for highway cruising or lighter loads). The wiring diagram shows how the control module, switches, and actuators are interconnected to facilitate the shift between these two gears. This proper electrical communication is paramount for the safe and efficient operation of the vehicle.

The complexity of the diagram can vary, but common elements include:

- Power source (battery)

- Control switch (usually mounted in the cab)

- Shift solenoid or actuator

- Speed sensors

- Indicator lights

These components work in tandem. When the operator engages the shift control, an electrical signal is sent to the solenoid or actuator. This signal, dictated by the 2 Speed Axle Wiring Diagram, then directs hydraulic fluid or engages an electrical motor to physically move the gears within the axle, thus changing the ratio. The diagram will detail the specific wires and their color coding, as well as the terminal connections on each component.

To further illustrate, consider this simplified breakdown of the operational flow:

- Driver activates the shift control.

- Electrical signal travels through the wiring as depicted in the diagram.

- Solenoid receives the signal and initiates the gear change.

- Indicator light confirms the new gear selection.

Occasionally, a 2 Speed Axle Wiring Diagram might also include information about diagnostic ports or fuses integral to the system. Understanding these details can significantly speed up troubleshooting when problems arise.

For those seeking a comprehensive understanding, referencing the specific 2 Speed Axle Wiring Diagram for your particular make and model is highly recommended. The information presented in the detailed diagrams provides the most accurate and reliable guidance for any electrical work.