Understanding the intricacies of electrical systems is crucial for anyone involved in their installation or maintenance. A key component in many industrial and commercial applications is the definite purpose contactor. Specifically, a 2 Pole Definite Purpose Contactor Wiring Diagram serves as the blueprint for safely and effectively controlling electrical loads. This article will delve into what these diagrams represent and how they function, providing a clear and accessible explanation.

What is a 2 Pole Definite Purpose Contactor Wiring Diagram and How Are They Used?

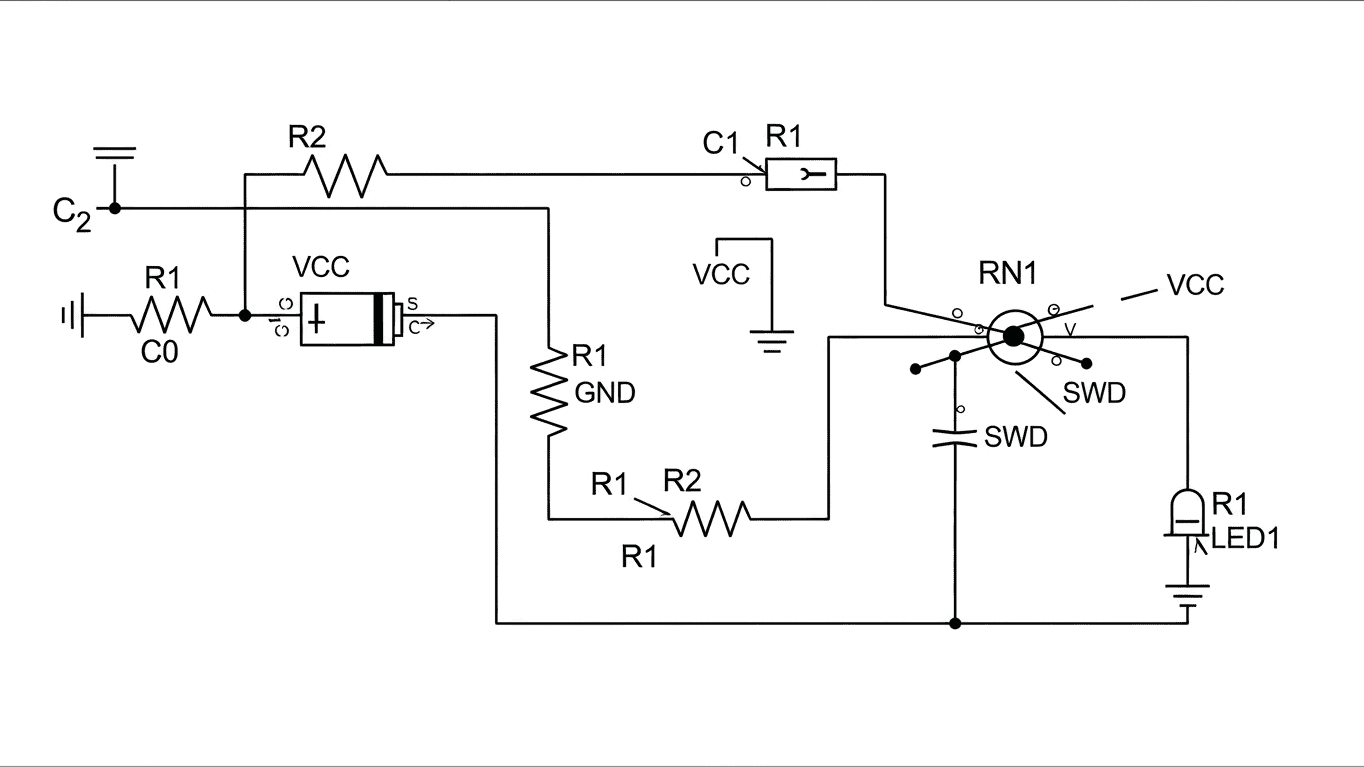

A 2 Pole Definite Purpose Contactor Wiring Diagram is essentially a visual schematic that illustrates how to connect a two-pole definite purpose contactor to a power source and a load. Definite purpose contactors are designed for specific applications, unlike general-purpose relays, and are often found in HVAC systems, refrigeration units, and other equipment requiring robust and reliable switching. The "2 Pole" aspect signifies that the contactor has two sets of contacts, allowing it to simultaneously switch both wires of a single-phase circuit, or two separate single-pole circuits. Properly understanding and implementing a 2 Pole Definite Purpose Contactor Wiring Diagram is vital for preventing electrical hazards, ensuring equipment longevity, and maintaining operational efficiency.

These diagrams are indispensable for electricians and technicians. They break down complex wiring into simple, understandable lines and symbols. A typical 2 Pole Definite Purpose Contactor Wiring Diagram will show:

- The power input terminals (often labeled L1, L2).

- The load output terminals (often labeled T1, T2).

- The coil terminals (usually labeled A1, A2), which receive the control voltage to energize the contactor and close the contacts.

- The control circuit, which dictates when the coil receives power.

Consider the following common scenarios where a 2 Pole Definite Purpose Contactor Wiring Diagram is essential:

- Single-Phase Motor Control: Switching the power to a single-phase motor, ensuring both hot and neutral (or two hot lines in a split-phase system) are controlled.

- HVAC Systems: In air conditioners or furnaces, these contactors manage the flow of power to compressors, fans, and heating elements.

- Refrigeration Equipment: Controlling the power to compressors and other components in commercial refrigeration units.

The following table provides a simplified representation of terminal identification:

| Label | Description |

|---|---|

| L1, L2 | Line/Power Input |

| T1, T2 | Load/Output |

| A1, A2 | Coil Terminals |

By meticulously following the 2 Pole Definite Purpose Contactor Wiring Diagram, one ensures that the electrical pathways are correctly established, allowing the control signal to actuate the contactor precisely when needed. This prevents back-feeding of power, short circuits, and ensures the load operates only when intended.

For clear and actionable guidance on wiring your specific 2 Pole Definite Purpose Contactor, refer to the detailed diagrams provided in the manufacturer's documentation for your particular model. This resource is specifically designed to offer the precise layout for your equipment.