Understanding the intricacies of a 2 Phase Stepper Motor Wiring Diagram is crucial for anyone looking to control precise movements in their electronic projects. Whether you're building a 3D printer, a CNC machine, or an automated robotics system, a correctly implemented 2 Phase Stepper Motor Wiring Diagram ensures your motor operates efficiently and reliably, delivering the exact positional accuracy required.

Decoding the 2 Phase Stepper Motor Wiring Diagram

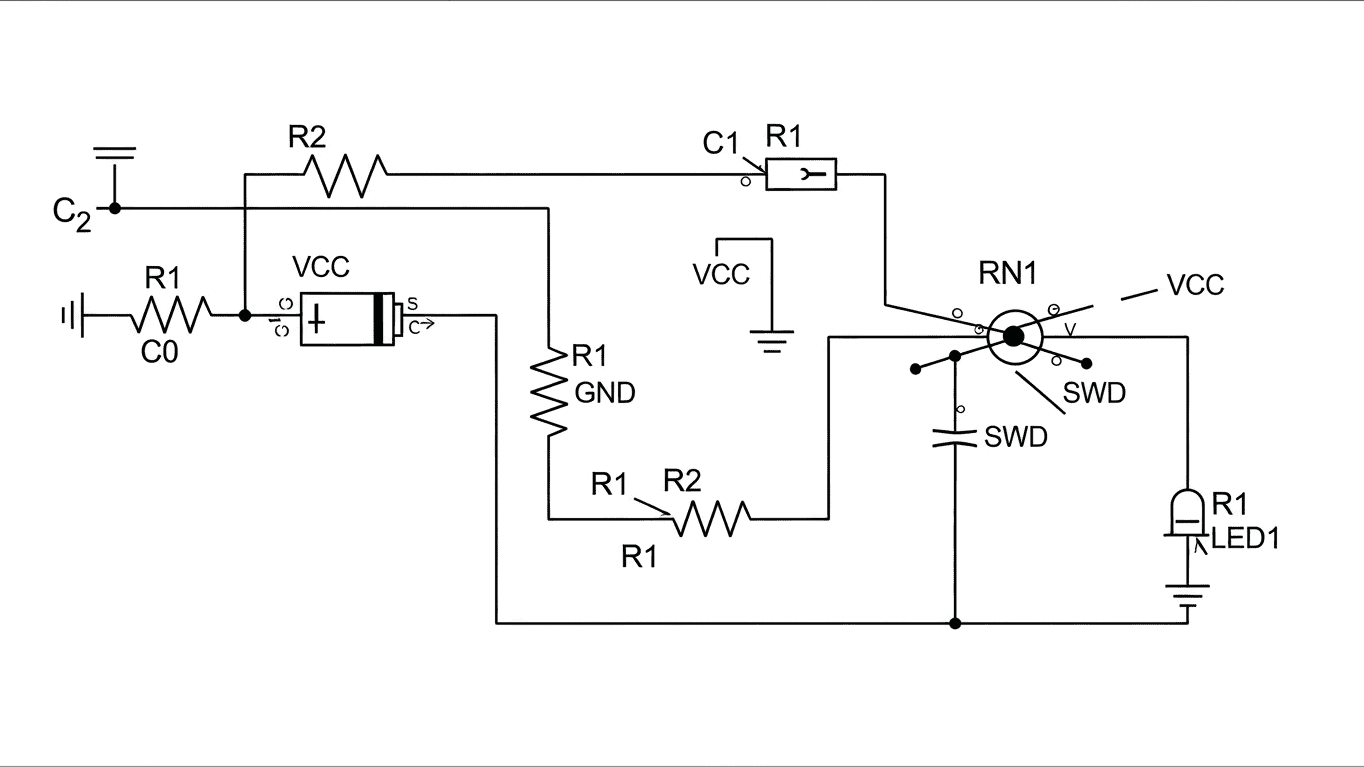

A 2 Phase Stepper Motor Wiring Diagram essentially illustrates how to connect the motor's coils to a compatible stepper motor driver. These motors are characterized by their ability to move in discrete steps, making them ideal for applications demanding high precision. Each phase of the motor typically consists of a set of windings. The driver's role is to energize these windings in a specific sequence, causing the rotor to advance one step at a time. The correct wiring is paramount for preventing damage to both the motor and the driver, and for achieving the desired motor performance.

Stepper motors commonly come in two main configurations: unipolar and bipolar. While the "2 Phase" designation generally refers to bipolar motors, it's important to recognize the distinction. Bipolar stepper motors have two distinct windings per phase, and the direction of current flow in these windings is reversed to achieve rotation. Unipolar motors, on the other hand, have center-tapped windings, allowing current to flow in one direction through half of the winding at a time, simplifying some driver circuitry. However, bipolar motors generally offer higher torque and are more efficient. A typical 2 Phase Stepper Motor Wiring Diagram for a bipolar motor will show four wires, each corresponding to one end of a phase winding. For unipolar motors, you might see six or eight wires.

Here's a breakdown of common wiring scenarios and considerations:

-

Bipolar Motors (4-wire):

- Two wires for Phase A.

- Two wires for Phase B.

-

Unipolar Motors (6-wire):

- Two common wires (connected to the center taps).

- Two wires for Phase A (one end of each winding).

- Two wires for Phase B (one end of each winding).

Here's a simplified table showing typical wire color assignments, though always refer to your specific motor's datasheet:

| Phase | Wire 1 | Wire 2 |

|---|---|---|

| A | Green | Yellow |

| B | Blue | Red |

When consulting a 2 Phase Stepper Motor Wiring Diagram, pay close attention to the labels and connections for the stepper motor driver. Drivers often have specific terminals for each phase (e.g., A+, A-, B+, B- for bipolar). Misconnecting these can lead to the motor not moving correctly or even becoming damaged.

To get started with your project, we highly recommend referring to the detailed diagrams provided in the specific documentation for your stepper motor and its accompanying driver. This will ensure you have the most accurate and application-specific wiring information at your fingertips.