Understanding the intricacies of a 2 Hp Single Phase Motor Wiring Diagram is crucial for anyone working with or maintaining these common electrical workhorses. This diagram serves as a visual blueprint, detailing how the motor's components connect to the power supply and auxiliary circuits, ensuring safe and efficient operation.

Decoding the 2 Hp Single Phase Motor Wiring Diagram

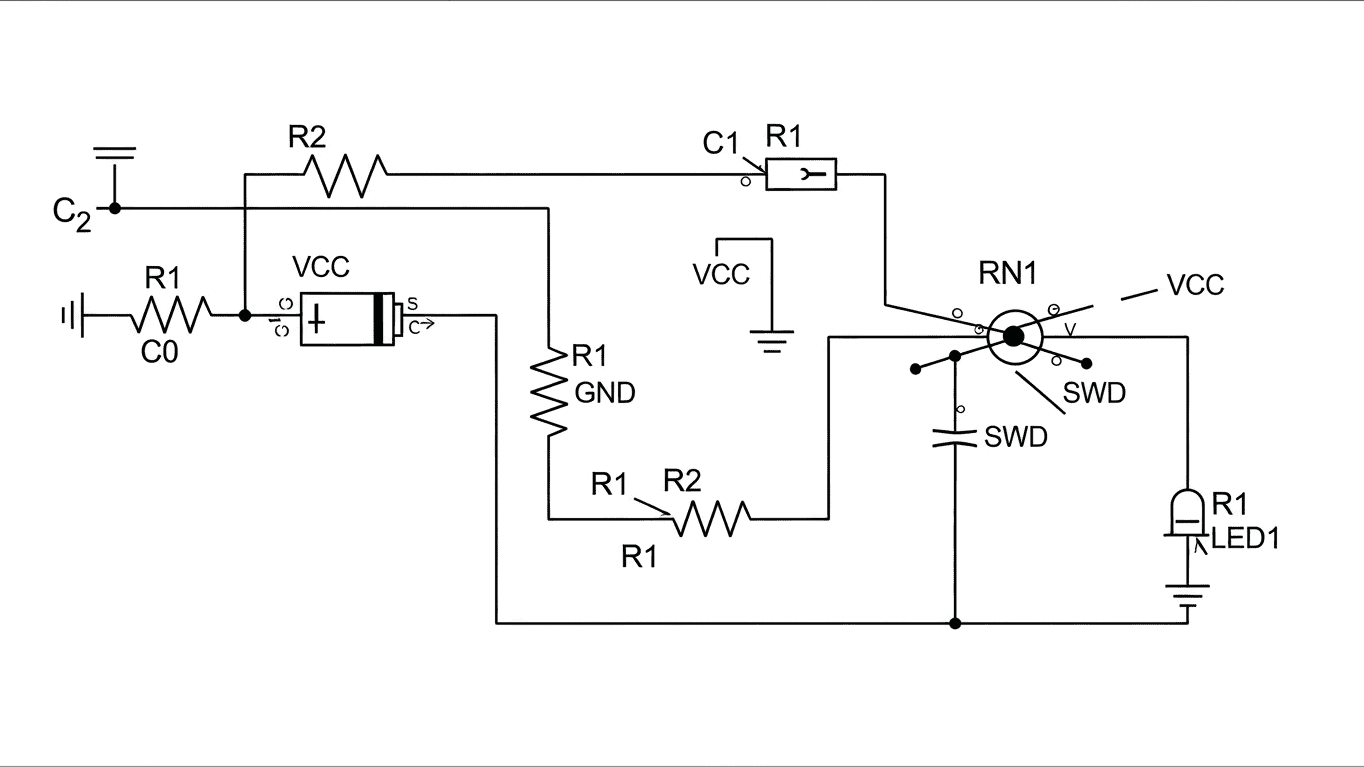

A 2 Hp Single Phase Motor Wiring Diagram is essentially a schematic that illustrates the internal connections of a single-phase electric motor with a horsepower rating of two. These motors are prevalent in a vast array of applications, from household appliances like washing machines and refrigerators to workshop tools such as drill presses and air compressors. The diagram helps electricians, technicians, and even skilled DIY enthusiasts identify the purpose and connection points of various parts, including the main winding, start winding, capacitor, centrifugal switch, and power terminals. Without a clear understanding of this diagram, troubleshooting electrical issues or performing installations can become a complex and potentially hazardous task. The accurate interpretation of a 2 Hp Single Phase Motor Wiring Diagram is paramount for both safety and operational integrity.

The purpose of a 2 Hp Single Phase Motor Wiring Diagram goes beyond mere identification. It guides the proper connection of the motor to the electrical supply, ensuring that the windings are energized in the correct sequence to generate the necessary starting torque and running power. Different types of single-phase motors, such as split-phase, capacitor-start, capacitor-run, or capacitor-start/capacitor-run, will have slightly varied diagrams due to their unique starting mechanisms. For instance:

- A split-phase motor diagram will show a start winding with higher resistance and lower inductance.

- A capacitor-start motor diagram will include a starting capacitor and a centrifugal switch to disconnect it once the motor reaches a certain speed.

- A capacitor-run motor diagram will feature a running capacitor that stays connected to improve efficiency and power factor.

These diagrams are indispensable for:

- Installation: Ensuring correct wiring to prevent damage or malfunction.

- Troubleshooting: Diagnosing faults by tracing electrical paths and checking component continuity.

- Repair: Identifying faulty components and understanding how to replace them.

- Maintenance: Performing routine checks and ensuring all connections are secure.

When examining a 2 Hp Single Phase Motor Wiring Diagram, you'll typically encounter symbols representing:

| Symbol | Component |

|---|---|

|

|