A 2 float switch wiring diagram is your key to understanding how to correctly connect two float switches into a system. Whether you're setting up an automated sump pump, a water level alarm, or a filling system, having a clear 2 float switch wiring diagram is essential for a safe and functional setup. This guide will break down what a 2 float switch wiring diagram entails and why it's so important.

The Role and Functionality of a 2 Float Switch Wiring Diagram

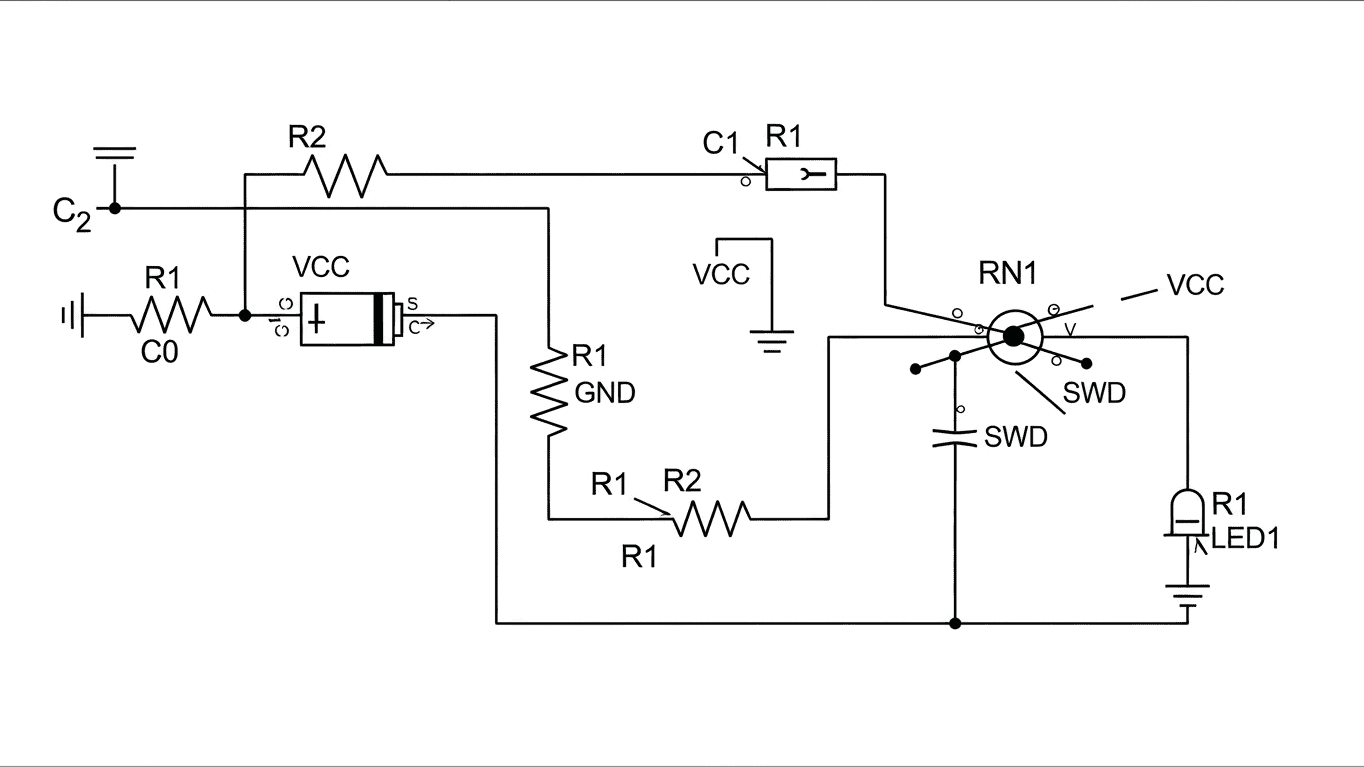

A 2 float switch wiring diagram illustrates how two float switches work together to control a device, typically a pump or a valve. Float switches are simple mechanical devices that react to changes in liquid levels. When the liquid rises to a certain point, the float inside the switch is pushed upwards, activating a set of electrical contacts. Conversely, when the liquid level drops, the float descends, deactivating the contacts. A 2 float switch wiring diagram shows how these two switches can be interconnected to create more sophisticated control logic. For example, one switch might be set to turn a pump on when the water level gets too high, while the second switch could be set to turn the pump off at a lower level, preventing the tank from running dry. The proper implementation of a 2 float switch wiring diagram is crucial for preventing equipment damage and ensuring reliable operation.

These diagrams are vital for several reasons:

- Ensuring correct electrical connections to prevent short circuits or damage to components.

- Configuring the switches for the desired operational sequence (e.g., pump on at high level, off at low level).

- Troubleshooting issues if the system doesn't function as expected.

Here's a typical scenario where a 2 float switch wiring diagram is used:

- High Level Activation: The first float switch is positioned at a higher point. When the liquid reaches this level, it triggers the switch, which then sends a signal to turn on a pump or open a valve to drain the liquid.

- Low Level Deactivation: The second float switch is positioned at a lower point. When the liquid level drops to this point, it triggers the second switch, which then sends a signal to turn off the pump or close the valve, preventing over-draining.

The specific wiring configuration will vary depending on whether the switches are designed to be normally open (NO) or normally closed (NC) and the type of power supply used (AC or DC). Understanding these nuances is where the diagram becomes indispensable. A typical 2 float switch wiring diagram might look something like this:

| Component | Connection Point |

|---|---|

| Power Source | Line (L) / Hot Wire |

| Float Switch 1 (High Level) | Terminal 1 (Common), Terminal 2 (NO or NC) |

| Float Switch 2 (Low Level) | Terminal 1 (Common), Terminal 2 (NO or NC) |

| Pump/Device | Controlled by the switches' outputs |

Always refer to the manufacturer's specific instructions that accompany your float switches, as they will provide the most accurate and safe 2 float switch wiring diagram for your particular model.

For clear and detailed visuals, we recommend consulting the provided wiring diagrams within the product manuals or official documentation. This will ensure you have the most accurate and up-to-date information for your specific setup.